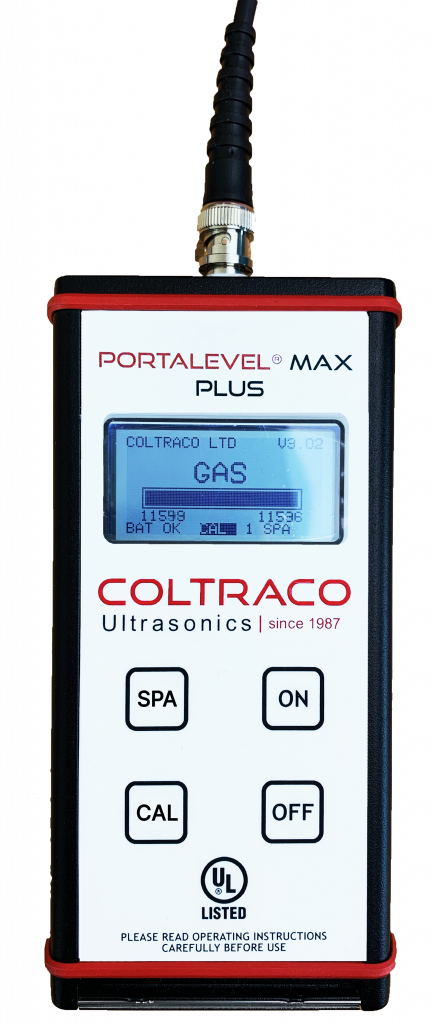

Coltraco Ultrasonics’ Portalevel® MAX PLUS is the world’s leading, and most accurate, contents monitor for liquified gaseous extinguishing systems. Coltraco’s newest British innovation follows the co-location of our Physicists and Scientists at Durham University, a globally outstanding centre of teaching and research excellence. The Portalevel® MAX PLUS features an upgraded intuitive user-interface displaying GAS or LIQUID to make testing fire suppression cylinders easy, and three independent calibration modes, carefully configured to account for the differences observed in such cylinders.

These new features build upon 35 years of Coltraco Ultrasonics’ expertise in the contents monitoring of liquified gaseous fire extinguishing systems. The upgraded intuitive user-interface and three independent calibration modes offers users unprecedented control, flexibility, and certainty by ensuring that the instrument is uniquely configured to the individual fire suppression cylinder being tested, and that you can view readings clearly. This accounts for the diversity in geometry and condition of fire suppression cylinders and fire suppression agents. The integration of these features with the Portalevel® MAX PLUS’s accuracy of +/-1.5mm has never been achieved before.

When used in combination with Coltraco Ultrasonics’ Portasteele® CALCULATOR, PermaMass® FEATHERWEIGHT, and Portascanner® AIRTIGHT 520, the Portalevel® MAX PLUS allows users to fully comply with ISO 14520-1:2015 (Gaseous fire-extinguishing systems – Physical properties and system design – Part 1: General requirements).

This facilitates the implementation of a comprehensive maintenance program as part of a strategic approach to business continuity, reducing the risk of accidental or ineffective discharges, and leaks in fire suppression systems not being identified, creating additional value leading to revenue reward, and delivering our vision of the Safesite™ on land and the Safeship™ at sea.

The Portalevel® MAX PLUS and the Portasteele® Calculator: Easy Liquified Agent Contents Monitoring

Pressurised liquified gaseous fire suppression cylinders, such as CO2, NOVECTM 1230 and FM200™ cylinders are constantly under pressure, with this pressure changing due to variations in temperature. These cylinders should be considered active, dynamic systems. It is reasonable to assume that these systems will slowly leak over time, which is very difficult to detect. Agent leakage or deterioration can cause an entire critical and life-saving fire suppression system to malfunction, and, if undetected, could result in the ineffective release of agent at that unforgiven moment when required to supress a fire in an emergency. Therefore, ISO 14520 regulations demand that these cylinders are tested to verify their contents.

9.2.1.3: The storage container contents shall be checked every 6 months as follows:

- Liquefied gases: for halocarbon agents, if a container shows a loss of agent in quantity of more than 5% or a loss of pressure (adjusted for temperature) of more than 10%, it shall be refilled or replaced

Furthermore, Annex F – System Performance Ventilation, recommends:

- Every 6 months: perform the following checks and inspections:

- for liquefied gases, check weight or use a liquid level indicator to verify correct content of containers; replace or refill any showing a loss of more than 5%

The Portalevel® MAX PLUS allows customers to go above and beyond ISO 14520 by enabling one person to monitor the liquid level of a large variety of halocarbon agents such as: FM200™, NOVEC™ 1230, Halon agents, FE-13™, FE-25™, NAF S III™ and all core Clean Agent systems in 30 seconds, rather than 15 minutes in a two-person team by weighing, to an accuracy of +/-1.5mm.

Building on 10 years of the Portalevel® MAX, sold globally to over 120 countries, three new and independent calibration modes within the brand new Portalevel® MAX PLUS provide much greater control when testing. Each mode is carefully configured to account for the differences observed in fire suppression cylinders and agents. When using the Portalevel® MAX PLUS, a reading is displayed which represents the relative strength of ultrasound passing though the cylinder and back to the sensor. This reading is what enables the differentiation between liquid and gas.

Cylinders that are perhaps older, or damaged, may produce results that make it difficult to find the liquid level. With the Portalevel® MAX PLUS, this issue can be overcome by using the instrument’s three new additional calibration modes. The ability to configure the device to a specific cylinder, despite the challenges associated with the diversity in fire suppression cylinders and agents as well as a new intuitive user-interface have never before been combined with the accuracy of the Portalevel® MAX PLUS, and greatly improve the ease of finding the liquid level.

Why Calculate Mass with the Portasteele® CALCULATOR?

Cylinder manufacturers do not usually provide the known liquid level of a filled cylinder; the only documented evidence of a cylinder’s contents is its fill weight. Furthermore, liquid level will fluctuate with temperature, as the density of the liquid changes. This fluctuation will vary for different agents and cylinder sizes. It is therefore important to relate any measured liquid level to the agent fill weight so that this remains traceable to actual cylinder contents as documented by the manufacturer or filling station.

The Portasteele® CALCULATOR uses the dimensional data of the cylinder provided by the user, in tandem with the liquid level of the agent within that cylinder measured by the Portalevel® MAX PLUS, to precisely calculate the mass of agent in the cylinder to within 1% of the true value.

Utilising the Portasteele® CALCULATOR and Portalevel® MAX PLUS in tandem allows users to comply with ISO 14520, and ensure that the agent weight present in a cylinder is within 5% of its design quantity by the direct comparison of liquid level measurement to printed cylinder agent fill weight.

This facilitates the better-faster-cheaper monitoring of storage container contents every 6 months or less by using an ultrasonic liquid level indicator, as suggested in ISO 14520, and provides unparalleled traceability in container contents measurement through the Portasteele® CALCULATOR’s ability to save results to the device, and securely export these in readable Excel format by email or USB.

Using an ultrasonic liquid level indicator to comply with ISO 14520 minimises the risk of physical injury to personnel by eliminating heavy lifting or accidental discharges, and improves asset safety by enabling the fire suppression system to remain operational, as cylinders can be kept in-situ, allowing customers to justify going above and beyond existing regulations as an integrated and essential element to their business activity.

The PermaMass® FEATHERWEIGHT: Inert Gas Agent Contents Monitoring for Agent Mass and Pressure Loss

Inert gas agent cylinders are pressurised, dynamic, and active systems. Therefore, ISO 14520 also mandates their monitoring every six months:

9.2.1.3: The storage container contents shall be checked at least every six months as follows:

- Non-liquefied gases: for inert gas agents, pressure is an indication of agent quantity. If a container shows a loss of agent quantity or a loss of pressure (adjusted for temperature) of more than 5%, it shall be refilled or replaced.

The easily retrofittable PermaMass® FEATHERWEIGHT uses fundamental mathematical principles to provide constant, real-time alerts to any mass loss and equivalent pressure loss in up to 12 inert gas agent cylinders to 10g, or less than 1% accuracy above 10kg total agent weight. This is an industry leading capability. Monitoring mass is the only method of measuring agent loss that is not affected by temperature or pressure. The PermaMass® FEATHERWEIGHT allows users to comply with ISO 14520 by ensuring that inert gas agent quantity in a cylinder is within 5% of its design concentration.

This information can be monitored centrally at the cylinder location, with the highest accuracy of constant monitoring and the ease of retrofitting complemented by the ability of the PermaMass® FEATHERWEIGHT to display the exact amount of agent loss during a leak event, including percentage loss in each cylinder, and pressure loss for Inergen systems. Without constant monitoring, a risk is generated in the very environment which it is designed to protect.

The Portascanner® AIRTIGHT 520: Enclosure Integrity Monitoring

Compartment leak quantification and airflow rate monitoring is essential under ISO 14520 where gaseous extinguishing systems have to be designed in relation to the discharging agent hold-time and discharging agent peak pressure, to ensure that fire extinguishing gases do not leak outside the enclosure.

ISO 14520-1:2015 (Gaseous fire-extinguishing systems – Physical properties and system design – Part 1: General requirements), Chapter 9.2 Inspection and Chapter 9.2.1 General clearly instruct that:

9.2.4.1 At least every 12 months it shall be determined whether boundary penetration or other changes to the protected enclosure have occurred that could affect leakageand extinguishant performance

Whilst room integrity is frequently monitored at the design stage of a fire suppression system through pressurisation tests, such as with a Door Fan Test, it is common for further tests to be completed infrequently once this initial inspection has been passed. Periodic tests every 12 months are often only visual inspections, which are unreliable.

The Portascanner® AIRTIGHT 520 builds on Coltraco Ultrasonics’ long history in watertight integrity monitoring for the Royal Navy, and is able to quantify leaks as small as 0.5mm in diameter and locate leaks ten times smaller than this, in a depressurised environment. This is an unprecedented level of accuracy and a unique capability globally. Coltraco Ultrasonics is the only company world-wide whose instruments are able to monitor level, mass, and precisely identify, measure, and quantify the size, extent, and severity of leaks.

Regular, simple, and accurate leak location and quantification testing with the Portascanner® AIRTIGHT 520 will reveal possible defects in your enclosure, in a complementary manner to any Door Fan Tests conducted. The Portascanner® AIRTIGHT 520 allows the ultrasonic quantification of leak sites in a depressurised environment, which has never been achieved before. Door Fan Testing can then be conducted at an appropriate moment, if required, once leakage points have been identified and repaired. Uniquely, during these tests, the Portascanner® AIRTIGHT 520 allows the location and measurement of air leaks, facilitating remedial action that is precise, immediate, and often low-cost.

The industrial integration of technological solutions offered by the Portalevel® MAX PLUS, Portasteele® CALCULATOR, PermaMass® FEATHERWEIGHT and Portascanner® AIRTIGHT 520 to existing problems will protect dynamic pressurised systems, the individuals that maintain them, and the structures they are working so hard to guard against fire, delivering our vision of the Safesite™ on land and the Safeship™ at sea.